正文

[转帖]POM包胶 TPE包POM 配方思路以及应用实例(2011-05-05 13:36:34)

标签:

POM与TPE-S的组合引起特别的兴趣,因为两种材料都有许多独特的性能。

POM的突出优点在于:

一优良的力学性能(高拉伸强度、冲击强度、刚度、耐疲劳性)

一优良的耐湿、发动机燃油、润滑剂、溶剂、中性化学品性

一优良的尺寸精度

一良好的电绝缘性

一抗蠕变

一低磨擦

一宽阔的操作温度范围

聚甲醛用在汽车、家用电器、设备装置、机械结构、工具、电子与消耗品工业中。特别要强调的是,它因良好的滑动磨擦性而用于许多活动部件,如齿轮件、偏转皮带轮、棘轮或调整杆,还因优良的回弹性而用于快速连接。

TPE的突出优点在于:

一可变硬度范围宽(邵氏A=10一邵氏D=60)

一低密度

一良好的回复性

一优良的力学性能

一噪音一阻尼高

一良好的耐老化性能和优良的耐臭氧性能

一宽阔的柔度范围以及在宽阔操作温度范围内较小的柔度变化

一良好的耐酸、碱性

一非常好的静磨擦

在相同或类似的工业部门也在聚甲醛中使用热塑性苯乙烯弹性体

(尤其汽车部件,家用电器工业)

因此特别需要聚甲醛(POM)与一种或多种热塑性苯乙烯弹性体(氢化苯乙烯嵌段共聚物)的组合满足下述要求:在其中,两种组分之间的粘结性比先有技术的明显提高,从而能以多组分注塑法广泛应用POM/TPE一组合,而无需机械锚固,如昂贵的凹割等.

POM包胶应用:在车辆结构中,作为其上已注塑有凸起密封体的固定卡、具有阻尼功能的固定元件,如用于发动机燃油管线、带有无一滑动接触表面的滑动开关、注塑上密封件的门锁罩和在POM部件上具有优良触摸性的一般软接触表面.

POM包胶配方思路:

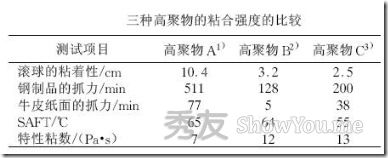

POM:首先进行改性,用10%苯乙烯/丁二烯共聚物改性,或者用5%SEEPS和5%SBS改性

TPE-S:以氢化苯乙烯嵌段共聚物为基础,它可以作为氢化聚异戊二烯/丁二烯橡胶((SEEPS)或作为氢化聚异戊二烯橡胶(SEPS)或作为氢化聚丁二烯橡胶(SEBS)。粘结能力SEEPS>SEPS>SEBS。

1)100%的SEPS线性嵌段共聚物,包括质量分数为18%的苯乙烯乙烯,Mw=5600;2)偶联的SEPS嵌段共聚物,包括质量分数为27%的SEP的二嵌段共聚物,质量分数为13%的苯乙烯,Mw=5800;3)偶联的SEBS嵌段共聚物,包括质量分数为35%的SEB二嵌段共聚物,质量分数为,13%的苯乙烯,Mw=5300;

定义补充:Thermoplastic elastomers (TPE) are the most appropriate material for the soft combination material for 2-C injection moulding. They can be divided into five principal groups:

1. TPE-O: based on polyoelfins (e.g. PP/EPDM and PP/NBR)

2. TPE-E: based on polyesters (polyetherester, polyesterester)

3. TPE-U: based on polyurethanes (polyetherurethane, polyesterurethane)

4. TPE-A: based on polyamides (polyether block amide)

5. TPE-S: based on styrene (e.g. SBS and SEBS)

实例:Hostaform POM + SEBS

Thermoplastic elastomers particularly suited for hard-soft combinations include the SEBS types (TPE-S based on styrene). They are characterised by a very favourable combination of properties (including high elasticity, good flexibility at low temperatures, exceptional resistance to water, acids and alcohols). They offer, what is more, a widely varied range of Shore hardnesses. Kraiburg, Germany, have developed special adhesion-modified SEBS types that can very effectively be combined with Hostaform. The combination, which is the subject of a joint patent application, enables the user to work with soft components that already have a Shore A hardness of 45. The first mass produced components were avail-able after only a few weeks. The ease of processing and the good adhesion should be emphasised.

The importance of combining hard plastics with soft materials in two-component injection moulding is rapidly increasing. The driving force behind this dynamic development is primarily the reduction in production costs through the disappearance of assembly work, multi-functional components and new design possibilities. Ticona offer plastics for the hard components in two-component injection moulding (2-C injection moulding): Hostaform (POM), Celanex (PBT) and Fortron (PPS).

已投稿到排行榜:塑料交流区